You are here

Kinetics & ProCeas® in Wet Chlorine (Cl2) process in Chlor-Alkali Plant

Mr Ethan Chen, Product and Application manager at Kinetics Technology Corporation (KTC), Taiwan, talks about his experience integrating AP2E products…

Can you introduce Kinetics Technology Corporation (KTC) and your activity?

Ethan Chen: KTC is a professional On-line Analyzer System Integrator, providing customer turn-key solution for petrochemical, chemical, semiconductor industries, etc. KTC is also awarded “Process Analytics Solution Partner” by SIEMENS since 2013.

As Product and Application manager, I am responsible to develop the on-line process application for represented products.

What problematic brought the end user to consider the ProCeas® as their best solution?

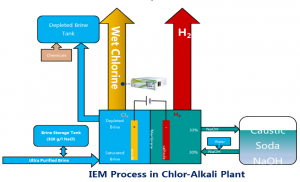

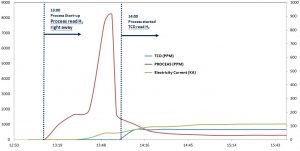

E C: By old technology with UV reactor transforming efficiency and limit (reactor needs > 85% of Cl2 to react with H2 to form HCl), the end user suffers “blind” situation during process start-up (only 30 to 45 mins. later, old TCD or IR technology could provide the reading). In Chlor-Alkali IEM process, any defects on the membranes will cause a catastrophic result if no real-time monitoring H2 in wet Cl2 (> 4% of H2 in Cl2 will cause explosion). In the past, the end user replied on experiences and “luck” to start-up the IEM process. Even if the process is successfully started, the old technologies could not provide stable and precise results due to its nature limit, the life time and efficiency of UV reactors.

What ultimately led the end user to select the ProCeas® versus other technologies?

E C: ProCeas® provides the end user the capability to measure absolute and direct H2, CO2, O2 simultaneously and without any inteference. The ProCeas® allows the end user to have reading of H2 right after IEM process start-up, for better safety control and process control (the behavior inside electrolyzer). Safety is always the most important thing for Chlor-Alkali plant.

Thanks to the technology of OFCEAS (ProCeas®), the end user can also measure absolute moisture (H2O), H2 and O2 in dry chlorine process simultaneously, for safety (H2, H2O) and quality (O2) control of chlorine (the ultimate product).

Figure 3. shows the location of sample tapping point.

In what context does Chlor-Alkali end user use ProCeas®?

- H2 in Wet Cl2 (IEM process)

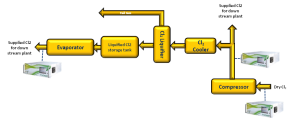

- H2/H2O/O2 in dry Cl2 (Compressor inlet and outlet & downstream of Cl2 evaporator)

Fig 1. Block Diagram of IEM process & analyzer system location

Fig 2. Comparison between technology OFCEAS and TCD