You are here

Our gas analyzers

Low pressure sampling extremely high resolution laser.

APPLICATIONS

- Biogas

- Natural Gas

- Combustion process

- Denox process

- Chemical process

- Continuous Emission Monitoring (CEM)

- Engine gas

- Gas purity

- Dryers

- Indoor air

- Safety

Advantages & Benefits

DIRECT MEASUREMENT

No sample pre-treatment.

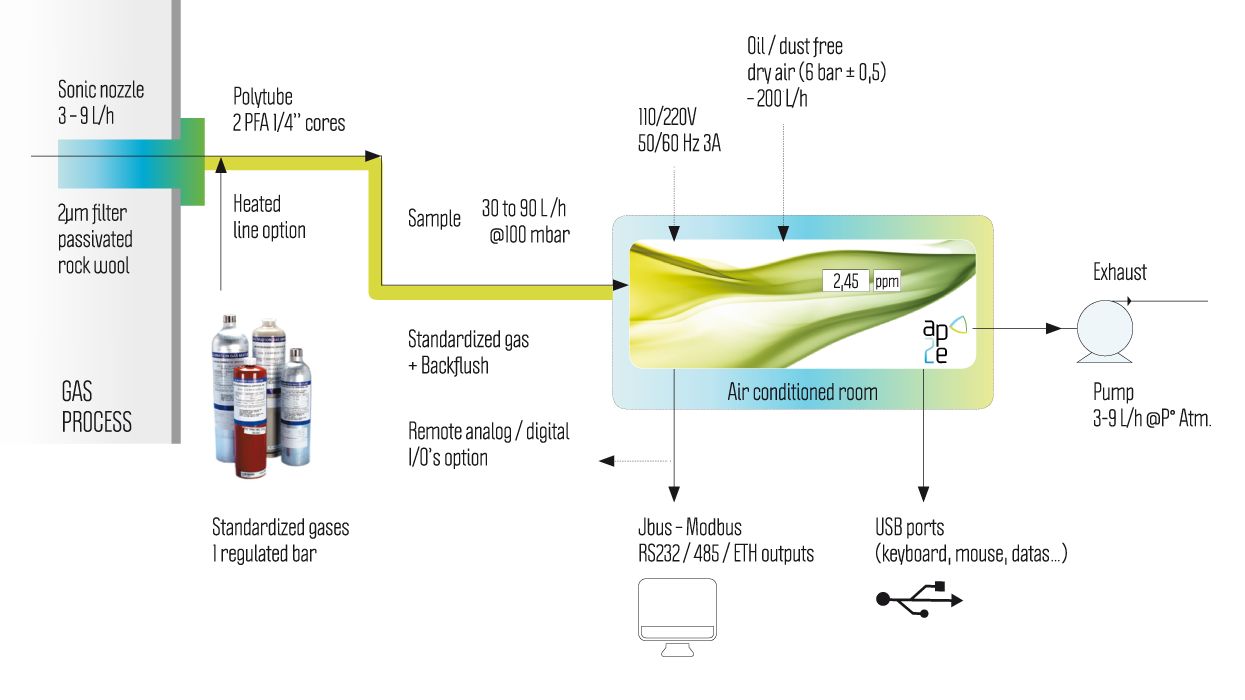

OFCEAS technology associated with low pressure sampling enables direct measurement. The low pressure in the sampling system removes any risk for chemicals adsorption/desorption and condensation in the line.

NO INTERFERENCE

OFCEAS technology associated with low pressure sampling provides exceptional selectivity, enabling simultaneous multi-component measurement without interferences, regardless of the matrix.

NO RE-ZERO; NO DRIFT

The zero information is contained in the signal, enabling automated and intrinsic re-zero of the analyzer.

EASE-OF-USE

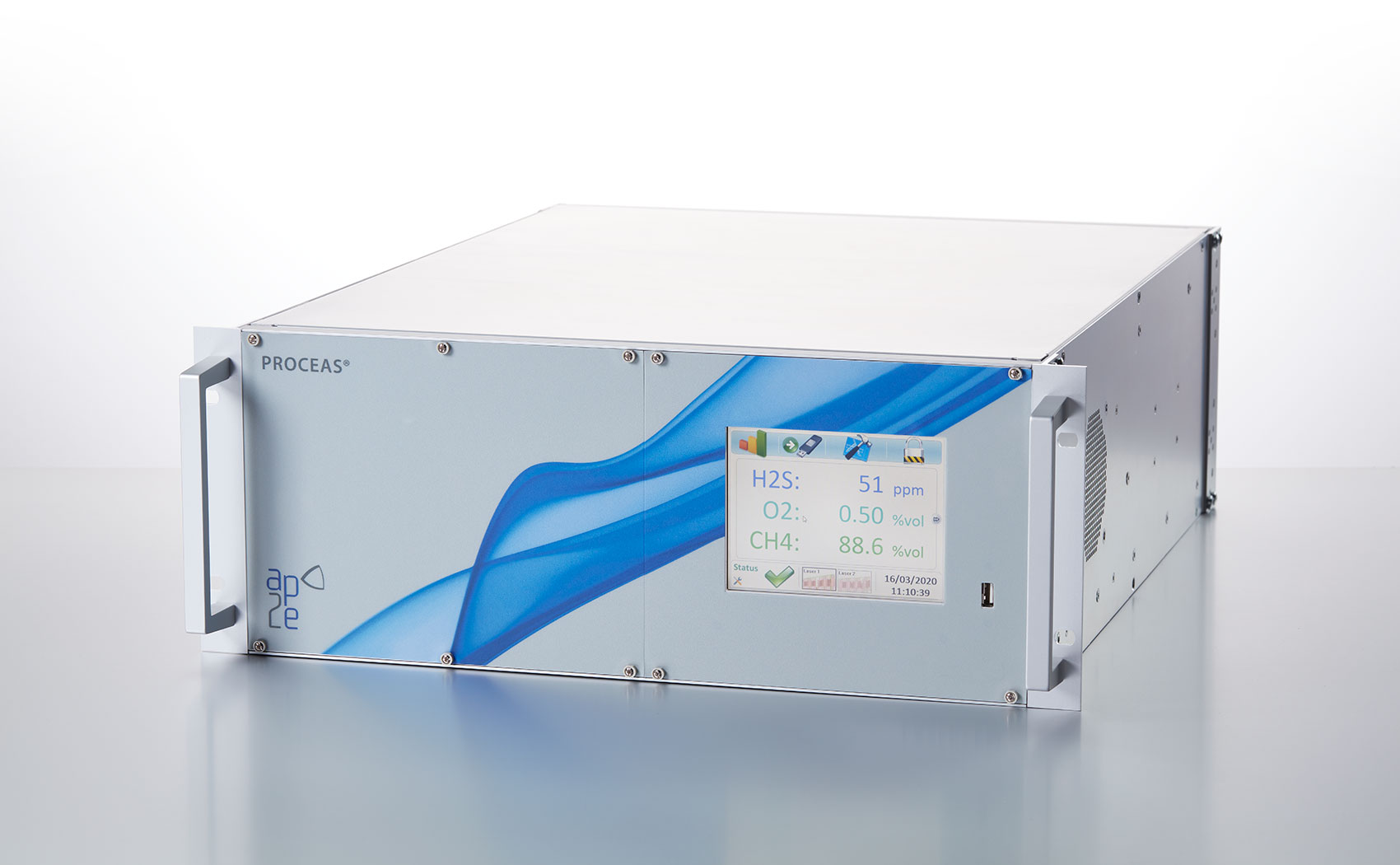

Our gas analyzers are pre-calibrated for your application. Iniially packaged in a standard 19”rack, it includes a touch screen interface and on-board PC for local / remote control and real time display / recording of results.

EASE-OF-INTEGRATION

Our gas analyzers allow digital (Ethernet, RS485, RS232, ModBus), analog and TDR I/O’s.

ROBUSTNESS

Our gas analyzers contain no optical moving parts and were designed and built strictly for industrial and on-board mobile applications.

LOW MAINTENANCE

High MTBF

In addition to containing no moving optical components, the IR sources (telecom type laser) are characterized by MTBF’s of 5 years.

CLEAN LINES / FILTERS

The low pressure sampling system enables low flow rates (3-9 L/h) without degrading response time. Accumulation of contaminants lines and filters is greatly reduced.

SAFE

ATEX compliant configuration available.

Analyzer specifications

| SAMPLING | |

|---|---|

| Flow Rate: | 3-9 L/H |

| Max. Temp.: | 600°C |

| Max. Humidity: | H2O(g) < 65% vol. – Standard H2O(g) < 65% vol. – Study Required |

| Pressure: | 1 atm. ±10 mbar @ sampling point |

| Sampling Line: | Ambient Temp. > 10°C et H2O <65% vol. > Simple polytube (no heating) Ambient Temp. < 10°C et H2O >65% vol. > 40°C heated line |

| DIMENSIONS | |

| Size: | Standard 19”, 4U rack. |

| 550 mm depth. | |

| Weight: | 20kg |

| Options: | Wall mounted ATEX compliant integration |

| ELECTRONICS | |

| Display/Control: | 5.7” color touch screen |

| PCOS: | Windows® |

| Software: | WinProCeas® |

| INSTALLATION REQUIREMENTS | |

| Operating Temp.: | 15-35°C – Standard 10-40°C – Optional |

| Power supply: | 200 W – 110-220VAC – 50-60Hz |

| Compressed Air: | 1-6 bar (oil free). Not provided. |

| I / O’s | |

|---|---|

| Standard: | Ethernet Protocol; RS 485 RS 232; ModBus. |

| Optional: | Analog I/O; TDR I/O. Other I/O’s on request |

| MEASURED PARAMETERS | ||||

|---|---|---|---|---|

| Gas | Typical range | |||

| Formaldéhyde | 0 – 100 ppm | |||

| H2S | 0 – 1 ppm / 0 – 5000 ppm | |||

| CH4 | 0 – 1000 ppm / 0 – 100% | |||

| CO | 0 – 1000 ppm / 0 – 100% | |||

| CO2 | 0 – 1000 ppm / 0 – 100% | |||

| H2 | 0 – 5000 ppm / 0 – 100% | |||

| H2O | 0 – 100 ppm / 0 – 100% | |||

| HCI | 0 – 1000 ppb / 0 – 1% | |||

| HCN | 0 – 10 ppm / 0 – 5000 ppm | |||

| HF | 0 – 500 ppb / 0 – 1000 ppm | |||

| N2O | 0 – 500 ppm | |||

| NH3 | 0 – 500 ppb / 0 – 1% | |||

| O2 | 0 – 100 ppm / 0 – 100% | |||

| NO | 0 – 5000 ppm | |||

| NO2 | 0 – 5000 ppm | |||

| Response TimeC: | 1 to 60 seconds. |

| Zero Drift: | none |

Diagram: from sampling point to analyzer