Vous êtes ici

Why do you need to control traces in hydrocarbons processes?

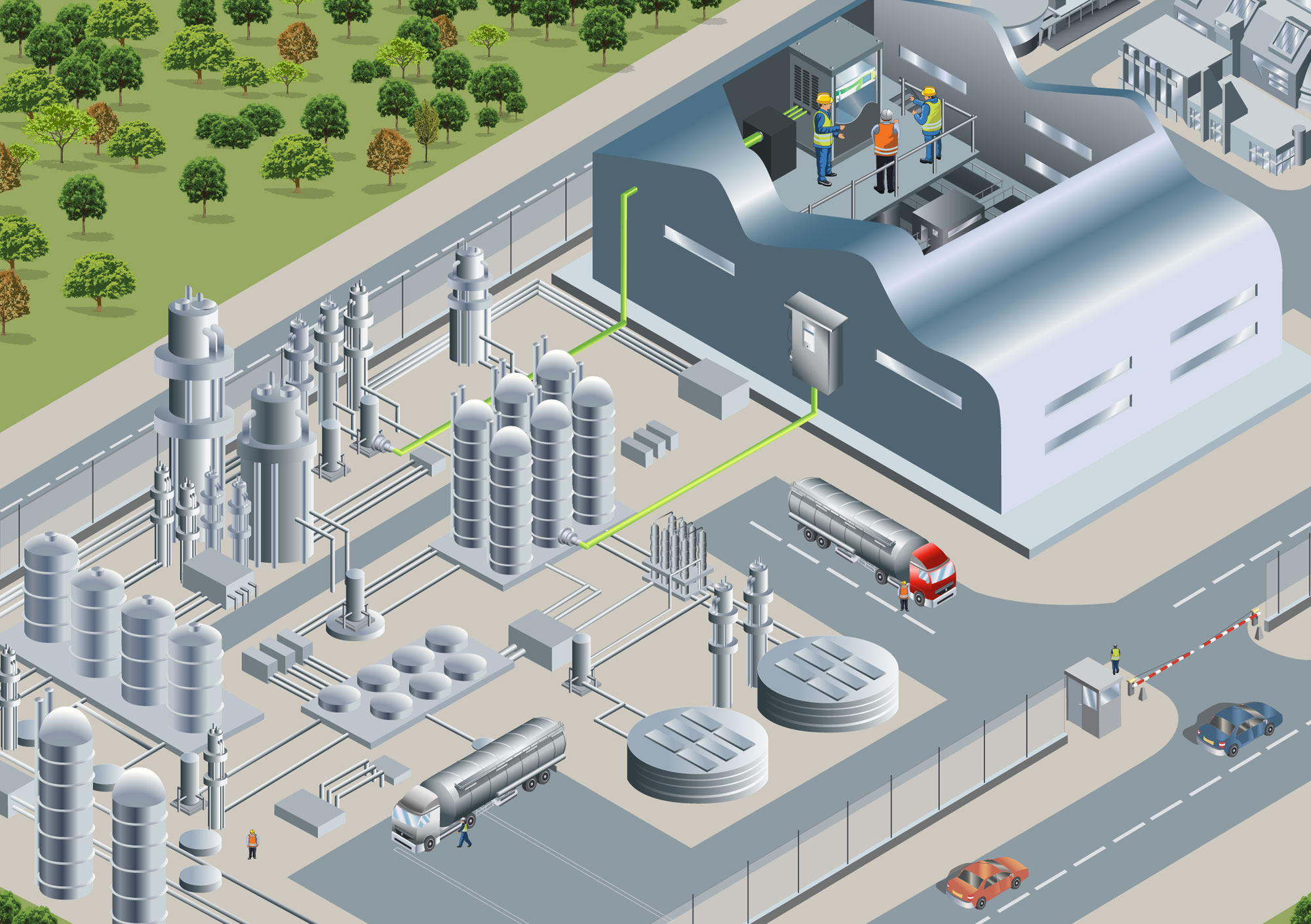

In many petrochemical applications, some gas components can be found at trace level. Their concentrations can fluctuate over time, and are depending on process parameters, or process feed.

Species like H2S, NH3, or H2O, can be considered as impurities (corrosive, toxic, etc.), and are often tracked in these gas matrices to insure the quality of the final gas product and the efficiency of the production process.

Technologies

Optical Feedback Cavity Enhanced Absorption Spectroscopy and Low Pressure Sampling

The ProCeas® uses the patented OFCEAS technology, based on extractive absorption spectroscopy.This laser based technology is able to measure gases down to ppb levels of concentration, with an unforeseen quality of measurement in terms of accuracy and repeatability. OFCEAS principle combined with Low Pressure Sampling (<30 mbar absolute) grants an enhanced gas selectivity, and therefore are not impacted by cross interferences between gases even in hydrocarbons matrices.

Self-calibration

ProCeas® has an integrated self-calibration of the measurement system, featuring no zero and span drift over time. ProCeas® is able to analyze a large range of gases with limited maintenance costs.

Key features

Installation

Analytical specifications

Proceas® trace analyzer in hydrocarbons

Is a complete pre-calibrated single or multicomponent (H2S, NH3, H2O etc.) laser infrared spectrometer for measurement of impurities.

| ANALYTICAL SPECIFICATIONS | ||

|---|---|---|

| Impurities | Rangea | LODb |

| H2S | on request | <0,05 ppm |

| NH3 | on request | <0,05 ppm |

| H2O | on request | <0,05 ppm |

| C2H2* | on request | <0,05 ppm |

a adjustable range on request

b limit of detection 3 sigma 60 seconds

* in pure ethylene (100% C2H4)

Gas backgrounds examples:

- Coke gas (60%H2, 10%N2, 7%CO, 3%CO2, 20%HC)

- Pulp and paper (75%N2, 10%CO2, 5%O2; 1%CO, NOx, SO2)

- And many other hydrocarbons applications